Knit line dispense techniques

Knit Line dispense techniques for cure-in-place and form-in-place gasketing

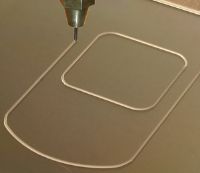

In cure-in-place (CIPG) and form-in-place (FIPG) gasketing applications, the gasket creates a seal used to protect critical components from air, dust, and moisture intrusion, and to prevent leaking and dampen vibration. Achieving a good knit line can help to eliminate voids and ensure bead fusion to deliver a reliable seal.

Knit line dispense techniques

Determining the appropriate knit line dispensing technique is an important consideration in dispense system programming and setup. Several knit line techniques include the overlap, parallel pass, butt joint, and sloping overlap.

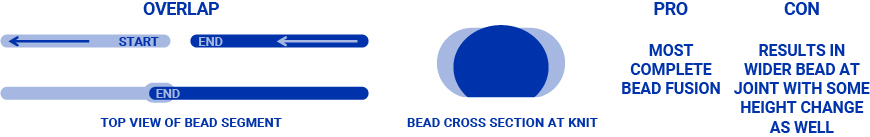

Overlap

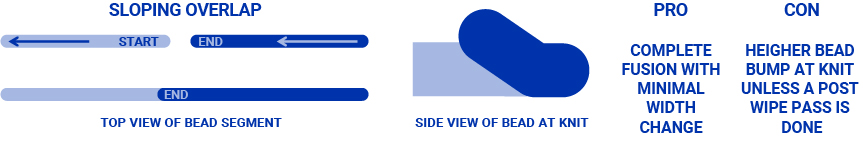

Sloping overlap

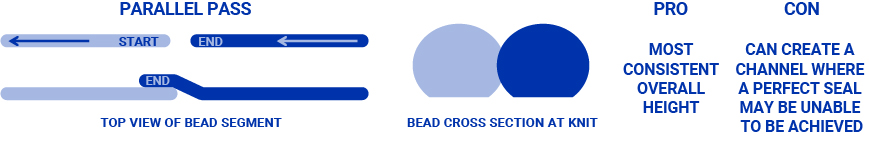

Parallel pass

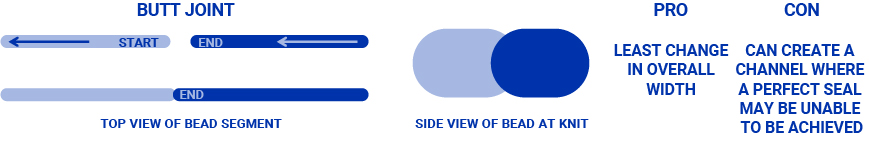

Butt joint

Automation techniques

Programming of the robotic dispensing system can also play a critical role in achieving bead path application requirements. Depending on part complexity and axis, adjustments to the automation motion can help optimise the dispensing process. Several automation motion techniques include the rake motion, traditional motion, reverse rake, and reverse rake and brake motion.

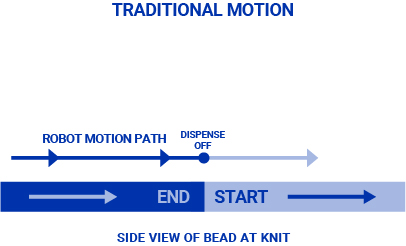

Traditional motion

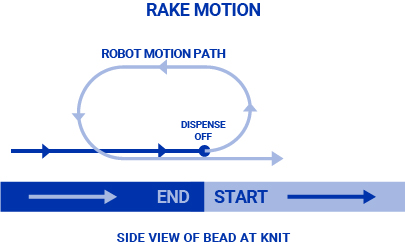

Rake motion

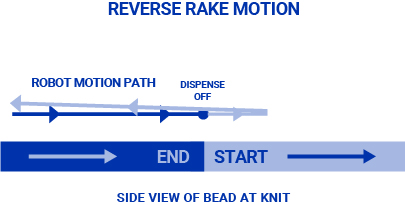

Reverse rake motion

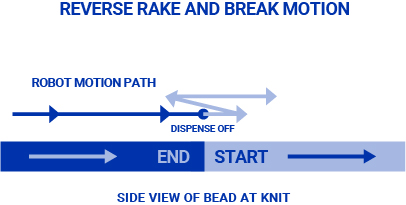

Reverse rake and break motion

Summary

In CIPG and FIPG, knit line dispense techniques and automation motion techniques play a critical role in proper bead dispense and achieving the desired knit line. In addition, here are some other important considerations:

• The rheological properties of the material

• Material viscosity

• Temperature

• Bead profile and functionality

• Dispense valve sealing technology

• Dispense parameters

• Equipment fixturing

• Substrate design and complexity

Contact an expert

Related articles

Increased production efficiency for Perform with Graco electric supply pumps

Learn how Perform achieved material savings, reduced electricity costs, and a significant noise level reduction through a "greener energy" solution.

Mondelēz Namur sticks with InvisiPac

After a six-month trial, the Mondelēz plant in Namur decided that the Graco InvisiPac was the ideal hot melt delivery system for them.

Aiming for optimal product development and technical support

The company wanted to use similar application equipment as their customers to emulate their production conditions when testing. Because they constantly develop new products Colorplas asks for market-leading equipment and solutions to gain the widest possible market coverage and application relevance...